Manufacturing Process

Precision in Manufacturing Leather Straps: Our Process

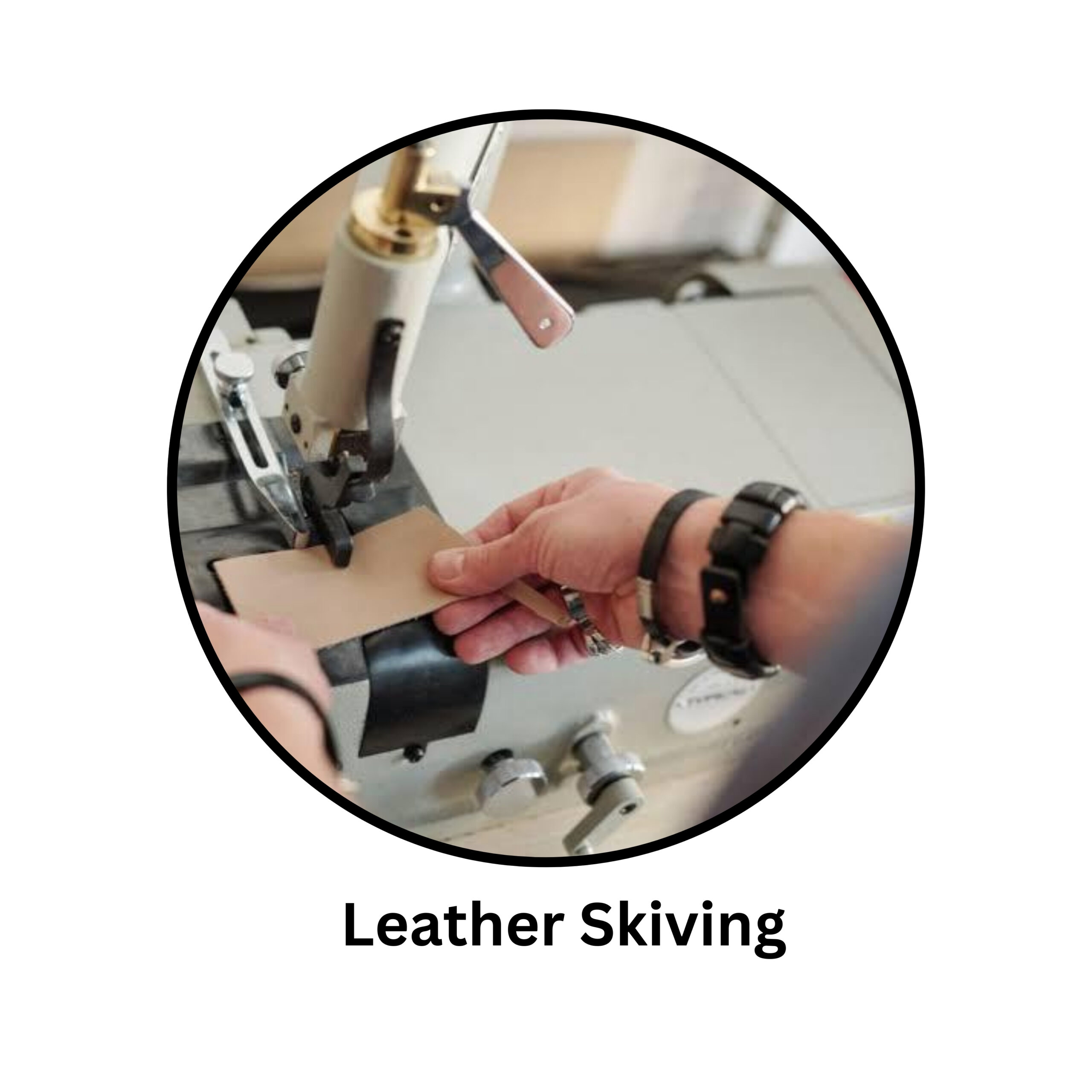

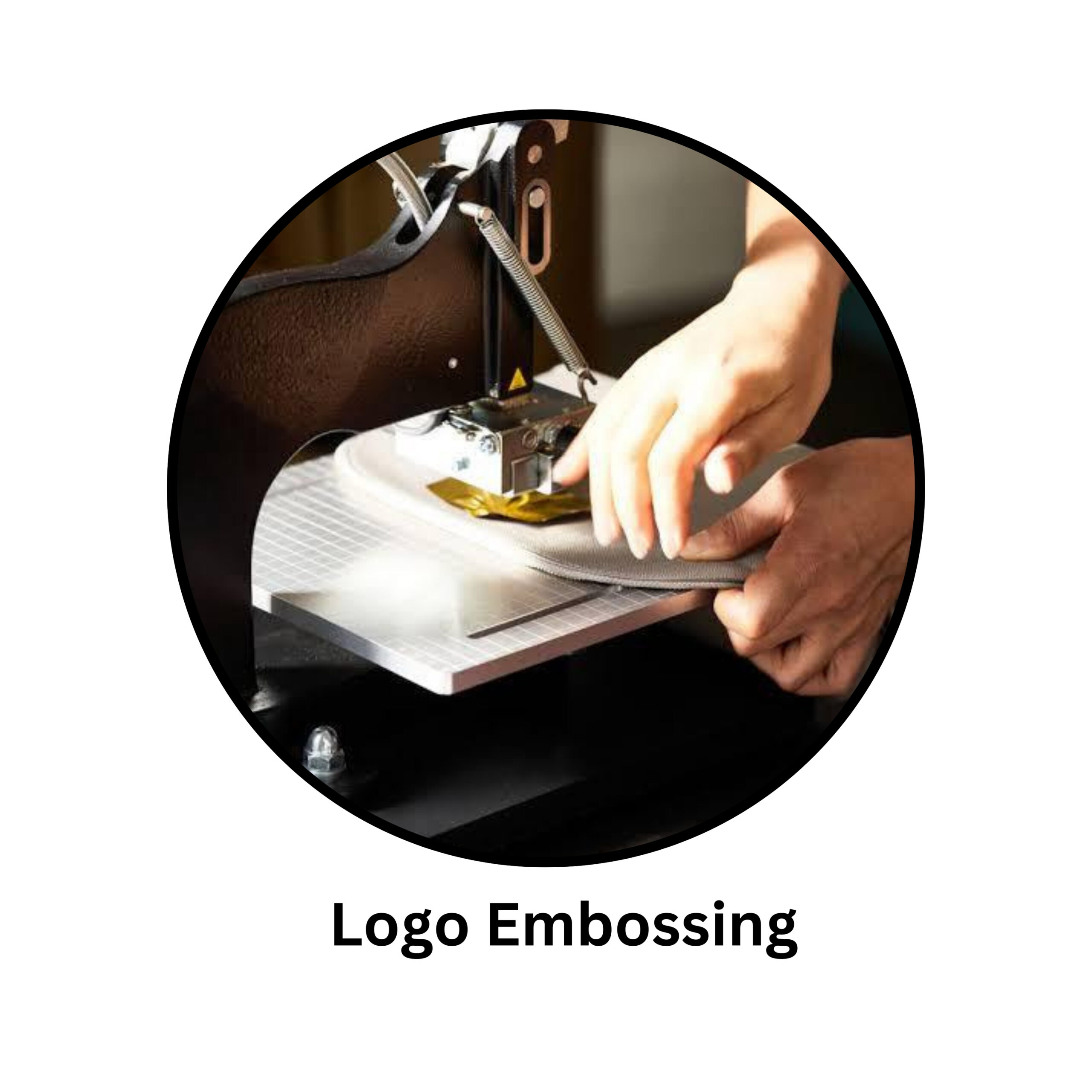

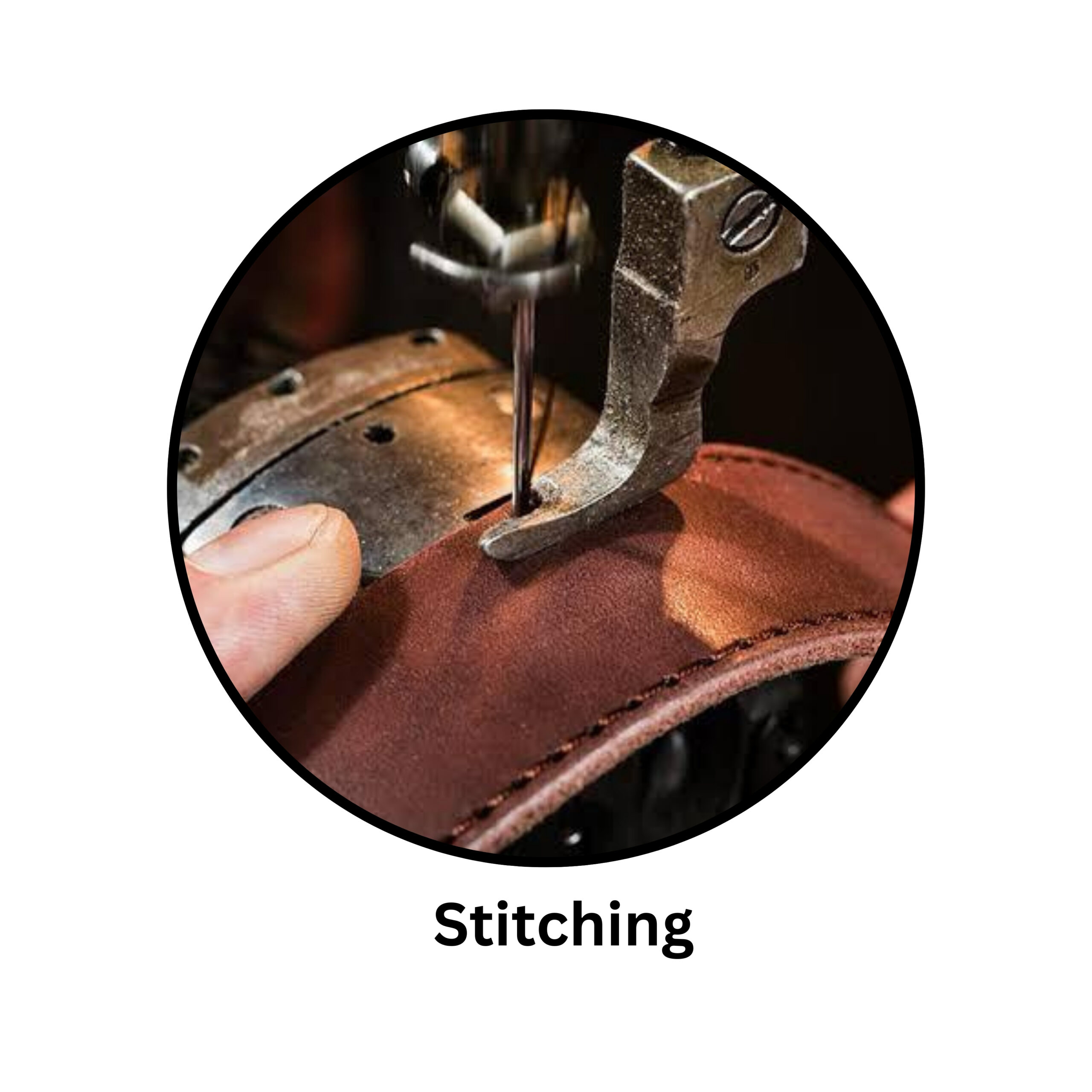

As a Leading Belting Leather Exporter and Certified Leather Exporter in India, Evaan International adheres to meticulous standards in our manufacturing process. Starting with precise cutting and splitting of high-quality leather, we ensure consistency and durability. Advanced techniques like leather press cutting, skiving, and heat crease line application enhance the strap’s functionality and aesthetics. Edge finishing, precise hole painting, and logo embossing add distinctive touches, complemented by expert stitching and secure buckle fixing. Each strap undergoes rigorous quality checks to meet our exacting standards before meticulous packing. Trust Evaan International for premium leather straps that exemplify craftsmanship and reliability.

Manufacturing Process

- Leather Strap

- Cutting Leather Splitting

- Leather Press Cutting

- Leather Skiving

- Heat Crease Line

- Edge Finishing

- Hole Painting

- Logo Embossing

- Stitching

- Buckle Fixing

- Quality Check

- Packing

Contact Evaan International for your Order:

Experience the difference with Evaan International. Contact us now to discover our exquisite leather straps and explore bespoke solutions tailored to your needs. Whether you’re seeking best leather belts in India, a leather belts manufacturer, Fancy Leather Belt for Womens or dog collars manufacturers, Evaan International delivers excellence in every product. Trust us to elevate your leather accessories with craftsmanship and reliability that surpass expectations.

Contact Evaan International today to discuss your requirements and elevate your leather products to new heights of quality and style.